Project Details

The project includes detailed research and implementation of automation systems in key manufacturing stages—material cutting, shaping, assembly, and finishing. Technologies like computer-aided design (CAD), programmable logic controllers (PLCs), and robotic arms are evaluated for their roles in improving fabrication accuracy and reducing material waste. A simulation model or prototype layout is used to demonstrate how different machines can work in harmony on a fully automated production line, minimizing downtime and human intervention.

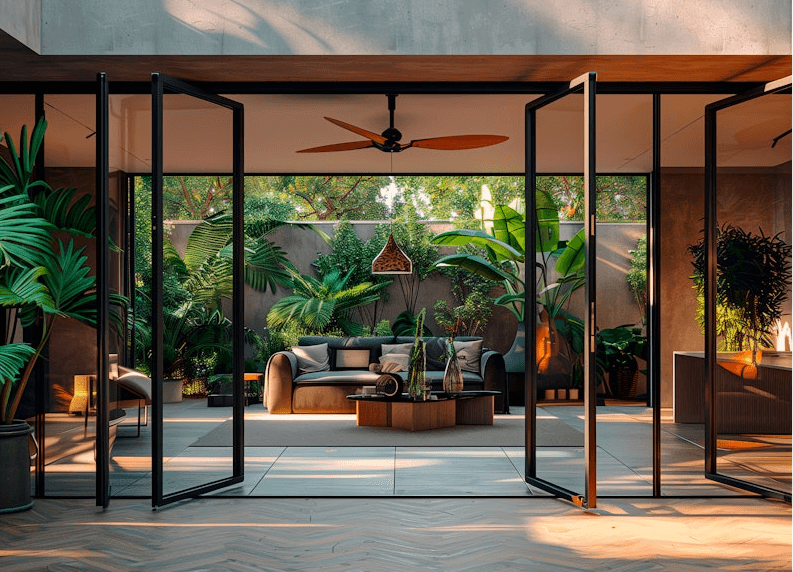

Automation in Window and Door Manufacturing explores the integration of modern technologies such as robotics, CNC machinery, and smart sensors into the production line of windows and doors. This project focuses on replacing or augmenting traditional manual labor with automated processes that ensure precision, speed, and consistency. The aim is to create a smarter, more efficient manufacturing environment that reduces human error, enhances quality control, and increases overall productivity.

Challenges We Face:

- Customization Needs

Clients often require unique sizes, styles, and finishes match their home or commercial space.

- Energy Efficiency Concerns

Ensuring optimal insulation and energy savings while maintaining style.

- Installation Complexity

Fitting windows and doors in non-standard or older structures can be challenging.

Our Expert Solutions:

- Seamless Installation

Our skilled team ensures precise fitting, even in complex structures, with minimal disruption.

- Energy-Efficient Technology

Our products feature double-glazing, thermal insulation, UV protection for better efficiency.

- Installation Complexity

Fitting windows and doors in non-standard or older structures can be challenging.

WORK PROCESS

Our Standard Work Thinking Process

All about precision, artistry, and attention to detail. Whether it’s capturing breathtaking landscapes, A perfect blend of modern and contemporary style. designing stunning interiors, or crafting seamless.